Here at Senior & Dickson we offer a range of services for a variety of different clients with quality as a constant aim to deliver the best products using refined processes. While we have specialised in toolmaking since 1981, our services have now grown to include concept design, plastic injection moulding, and we even now offer overseas tooling. Learn more about the injection moulding and toolmaking services we offer below.

Our talented team of design engineers can create anything from a 2D sketch or computer aided design to help visualise each plastic injection moulding project.

Find Out More

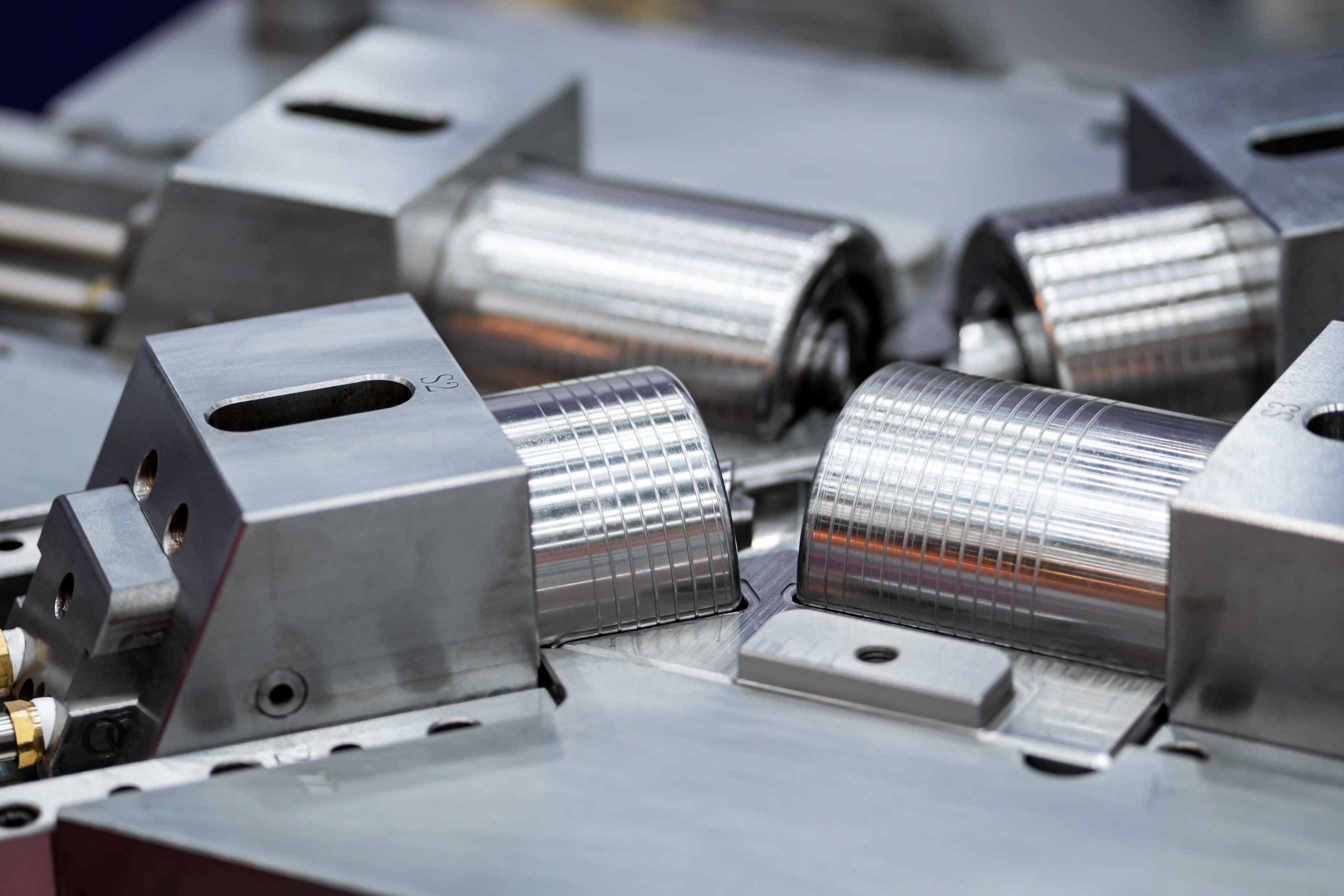

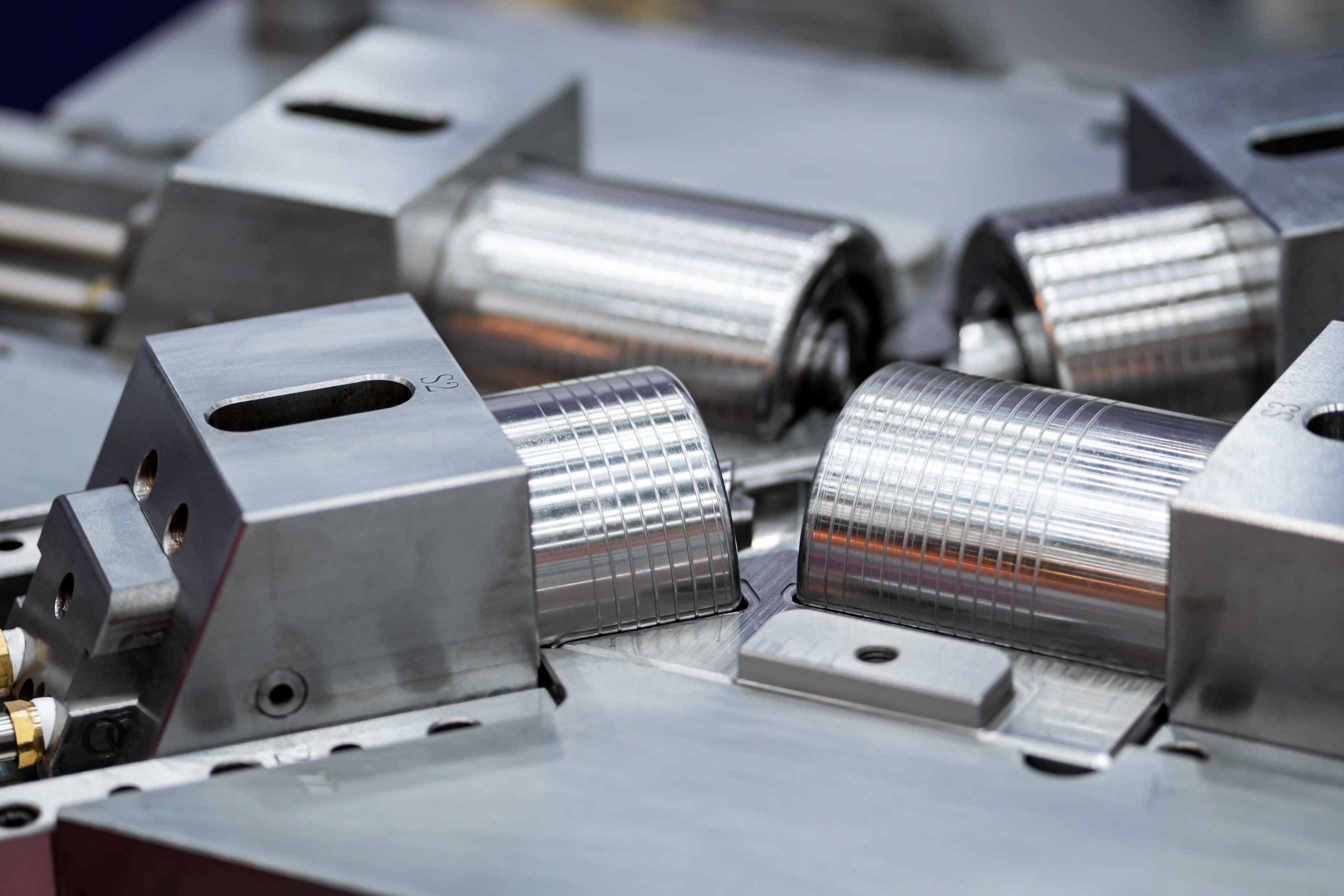

We have been manufacturing plastic injection mould tools for over forty years, refining our processes to give you long-lasting durability and effectiveness.

Find Out More

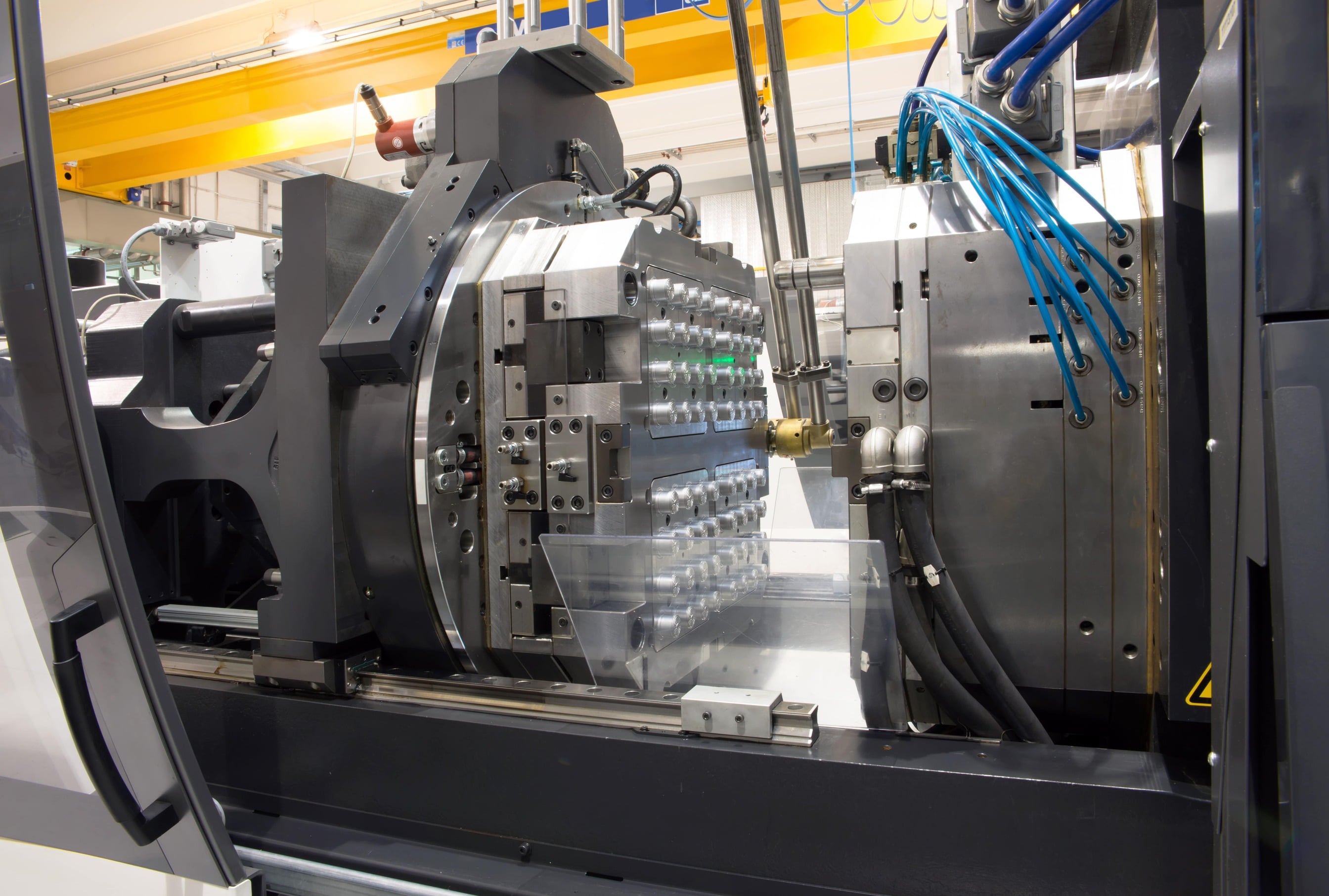

Senior & Dickson offer unparalleled injection moulding services. Our workshop contains state of the art machinery to help us bring your project to life.

Find Out More

Our trusted overseas suppliers have an open line of communication to our project management team to make sure that each project is completed in a timely manner, and to your specifications.

Find Out More